3DNextech, a startup specializing in the development of solutions related to the world of additive manufacturing and 3D printing, which thanks to its innovative technologies promises to revolutionize the plastics production chain, announces that it has closed an investment round of 1.5 million euros. The transaction sees the entry into the corporate structure of Eureka! Venture, through the Eureka! Fund I – Technology Transfer, lead investor of the round alongside RoboIT, the Technology Transfer Hub for Robotics set up by CDP Venture Capital, of the regional co-investment fund Toscana Next , set up and managed by CDP Venture Capital and underwritten by the main foundations of banking origin in the Tuscany Region (Fondazione CR Firenze, Fondazione Cassa di Risparmio di Lucca, Caript Foundation, Monte dei Paschi di Siena Foundation) to maximize investments in innovation for the territory, as well as a group of business angels. This funding round is aimed at consolidating 3DNextech’s position on the market, further developing the company’s growth strategy created with the aim of replacing the concept of mass production with that of mass customization thanks to digital manufacturing, which makes it possible to produce at zero kilometer and therefore reduce energy use and environmental impact. With a specific focus on 2024 and 2025, the future roadmap is based on the expansion of technological solutions, supported by the consolidation of the team and the strengthening of the network of partners in Italy and abroad. The startup’s recent participation in the 2024 edition of CES in Las Vegas is also part of this perspective. “We renew our confidence in additive manufacturing technologies, which confirm the potential for international growth, with valuations that are still attractive despite the physiological correction underway after the excesses of recent years. With 3DNextech we enter the promising segment of finishing objects produced with additive manufacturing, thanks to an innovative physical-chemical process that with a lower environmental impact allows the products to be ennobled, eliminating the numerous processes and traditional post-production processing and finishing techniques”, says Stefano Peroncini, CEO of Eureka! Venture “It is a source of pride to have valuable partners at our side who demonstrate that they believe in our mission and in the solidity of our project,” explains Andrea Arienti, CEO and founder of 3DNextech, in a note. Thanks to the strategic collaboration with Eureka!, and the entry of new investors, we are ready to continue further along our development path: 2024 is the year in which the growth strategy takes concrete shape, with significant investments and collaborations with companies ready to take advantage of our innovative solutions. We aim to triple the current team, double our turnover and look forward to a new Series A round to be completed in the first quarter of 2025.” «3DNextech, a spin-off of the Sant’Anna School of Advanced Studies in Pisa, convinced us for the solid foundations of scientific knowledge possessed by the team and for the ability to enhance this know-how through the development of a technology and a patented process capable of responding, in terms of greater sustainability, scalability and versatility of the proposed post-processing solutions, to the needs of a vast market made up of companies of various sizes and in different sectors,” says Anna Amati, partner of Eureka! Fund . “The technology developed by 3DNextech evolves the additive manufacturing landscape by equaling or even surpassing plastic products obtained through traditional industrial processes. This not only offers new opportunities for design and customisation, but also contributes significantly to environmental sustainability, reducing dependence on more polluting production processes,” comments Claudia Pingue, Head of the Technology Transfer Fund at CDP Venture Capital. With the RoboIT Hub, we will continue to closely monitor the progress of 3DNextech and offer our support to the journey of this technology.”

Innovation

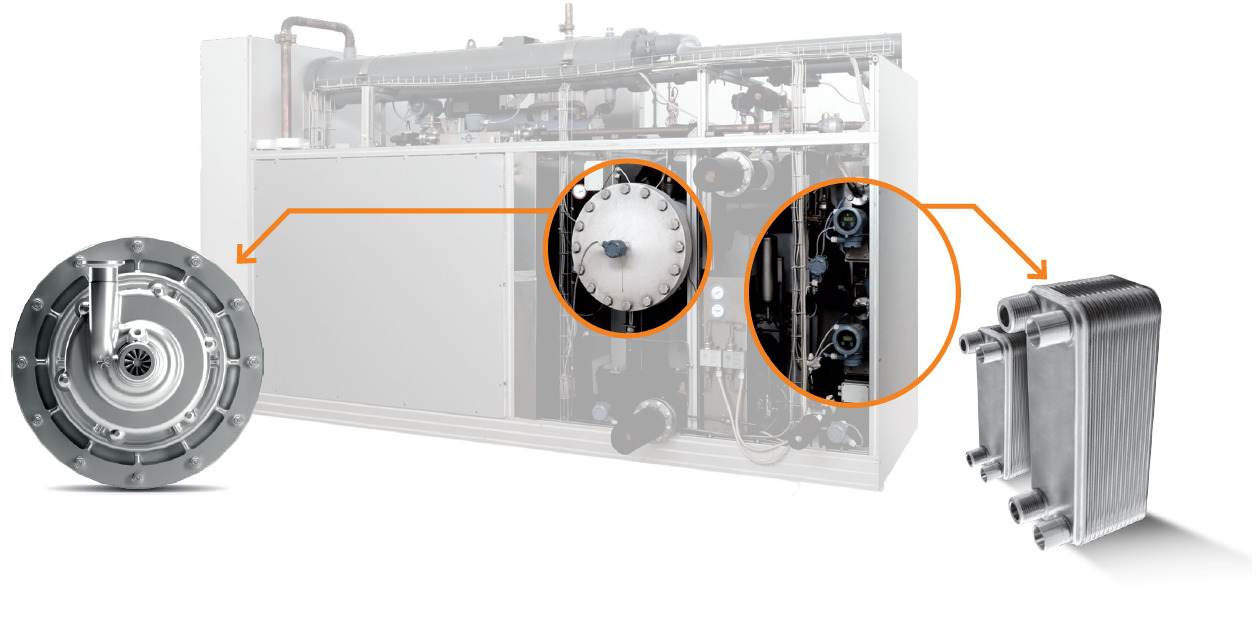

Using thermoplastic polymers such as ABS (Acrylonitrile butadiene styrene) or cellulose derivatives, three-dimensional creations often have small imperfections and ripples that make the surface wrinkled and unpleasant to the touch and eye. And above all, they make the product devoid of the physical and mechanical characteristics essential for industrial uses and not only comparable to those of products made with traditional methods. To solve this problem, 3DNextech has developed a technology based on an innovative chemical-physical process and a wide portfolio of patents, some of which have already been granted internationally (USA, China, Japan, Russia). The objects are processed in such a way as to make them malleable: the polymer chains of the plastic are realigned and, in the finishing operations, the objects become shiny and resistant, waterproof and ready to be painted or metallized. In addition to giving mechanical advantages to individual products, 3DNextech technology enables a whole new supply chain for the production of plastic objects, because it is possible to obtain products of comparable quality to injection molded ones, but producing only in the necessary quantity and directly on site. The first device to integrate this technology is 3DFinisher , the finishing station to be used as a complement to a 3D printer that is able to smooth out the imperfections of the object and return a finished product in every single aspect. The fields of application of this technology are the most varied, from automotive to design, from boating to the medical sector. Founded as a spin-off of the Sant’Anna School of Advanced Studies in Pisa, 3DNextech immediately specialized in the development of products and technologies related to the world of additive manufacturing and 3D printing. The entry of the first business angel allowed the company to take its first steps, but the turning point came first with the entry of A11 Venture with a strategic capital increase, which made it possible to further expand research and development horizons. Then with the entry of CDP Venture Capital, which through a convertible of the Relaunch Fund has recognized and supported the value and solidity of the 3DNextech project, helping to build an even more fertile ground for innovation. Recently, Electrolux, a leading manufacturer of household appliances, has chosen to include 3DNextech among its additive manufacturing partners in their acceleration program at the Innovation Factory in Porcia.

ALL RIGHTS RESERVED ©