Caracol, the scaleup operating in the field of large-format 3D printing, which in March 2023 closed a projectworth over 10 million euros and which the previous year had told Startupbusiness about its growth and development plans, continues its growth process aimed at giving substance to the mission of spreading the adoption of the technology known by the acronym LFAM which stands for large format additive manufacturing, and thus promote the spread of a more efficient, flexible and sustainable industrial production process.

Founded in Milan in 2017, Caracol has experienced rapid international growth to date, putting together a team with multidisciplinary skills. The company has invested in the development of its additive manufacturing technology and taking a strong service-oriented approach. This led to theopening of the last two facilities near Milan, the renovation of its ISO 9100 certified LFAM production facility, up to the opening of a North American market office in Austin in the US state of Texas, last year. Today, Caracol is present with four offices around the world and a fifth will soon be added, as announced by CEO Francesco De Stefano during the inauguration event of the new facilities, which anticipated the opening of the new office in Dubai. to serve customers in the Gulf Cooperating Council (GCC) area.

“The achievement of this milestone today is a source of great satisfaction for our entire team. It is a further step towards the evolution and expansion of the possibilities of large 3D printing in manufacturing and the realization of our vision in the world of advanced industrial production,” De Stefano, who is also co-founder of the scaleup, said in a statement. Our Italian offices are the core of our global operations, and this expansion will allow our team, partners and customers to reap even more satisfaction from the adoption of these technologies. Their success will be a further driving force towards the creation of a new paradigm of industrial production, which we have always pursued in the company and which is part of our vision”.

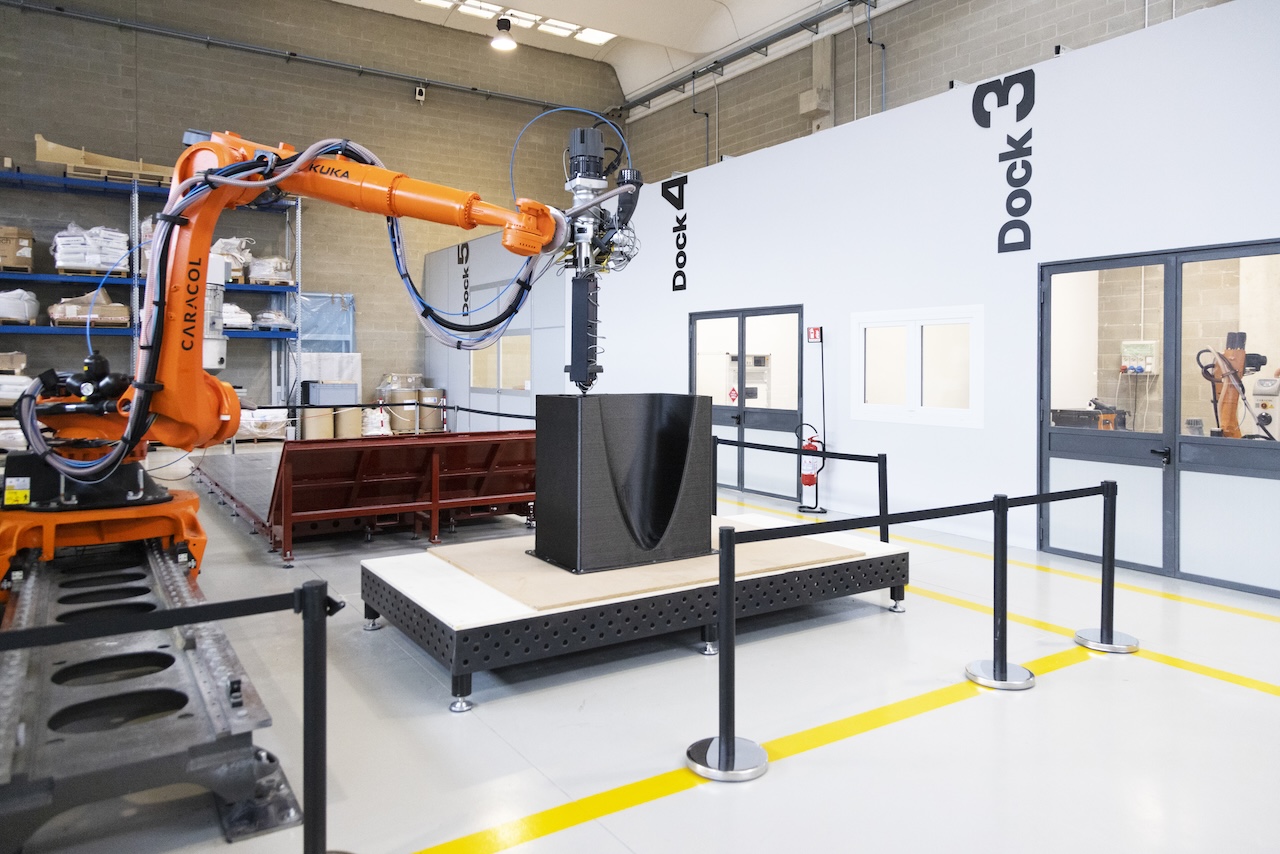

On February 1st Caracol has officially opened two new locations. A first assembly and test plant, where the company’s Heron AM systems come to life Tailored to customer requirements, they are then thoroughly tested and tested before installation at their respective locations. The team involved in these operations also takes care of the correct and effective design and preparation of the technology environment within the customers’ production plants. The second location is the innovation hub, a structure designed to house all the activities of the R&D team. In this space, several laboratories are dedicated to the development of the technology and integrated processes provided by Caracol: from the qualification of new materials, to the development of software, hardware and automation, to the experimentation of polymer and metal 3D printing processes, here the company works to improve the performance of its technology, helping to raise the level and quality of large-scale additive manufacturing processes more and more.

“Our work is focused on the production and application needs of our customers. The opening of these two state-of-the-art locations will allow us to further grow in providing high-quality and reliable technological solutions, designed for efficient and sustainable production,” says Paolo Cassis, COO and co-founder of Caracol.

“To see partners and customers that Caracol has had the pleasure of working with over the years join us from all over the world to celebrate this milestone is truly extraordinary. Our success is only possible thanks to the fantastic people and companies we have the pleasure of working with every day,” adds De Stefano.

Customers from all over the world

In addition to Caracol’s factories and European headquarters, the company took its guests to the Artwood Academy, a technical and vocational training school in the manufacturing sector, where Caracol shared the stage with local institutions and with some of the partners who are carrying out projects with Heron AM industrial 3D printing platforms. Armando Alves, CEO of Portugal’s Solidtech, shared their experience in 3D printing nickel shell housings, intended for the production of automotive dashboards; Massimiliano Zulli, marketing manager of the Italian company Treddy he talked about a project for the marine industry, in which finished superstructural parts such as yacht t-tops were printed entirely in 3D; Dominic Wright, CEO of UAE-based Generation 3D, talked about the work his team is doing, 3D printing architectural projects such as the Dubai Municipality’s booth at the recent COP28 conference; Faisal Alamer, CEO of Saudi Namthaja showed the process of replacing traditional technologies with large format additive manufacturing solutions that is taking hold in industrial production in the Gulf region; and Michael Gorski, CEO of U.S.-based Filament Innovations, shared the results obtained by replacing the metal bending process with robotic 3D printing, for the creation of custom-designed technical cabinets.

The experiences shared by the Caracol partners have highlighted the impact of this technology and in particular of the LFAM Caracol printing systems on industrial production, giving space to a real perspective for the future of industrial production, which changes the processes and the approach to design, engineering and production itself with the ultimate aim of achieving greater efficiency, optimization of performance, costs and delivery times; flexibility and freedom of design and customization; and sustainability from the selection to the most effective use of raw materials, including recycled and recyclable ones, and resources such as the reduction of water and energy consumption.

ALL RIGHTS RESERVED ©